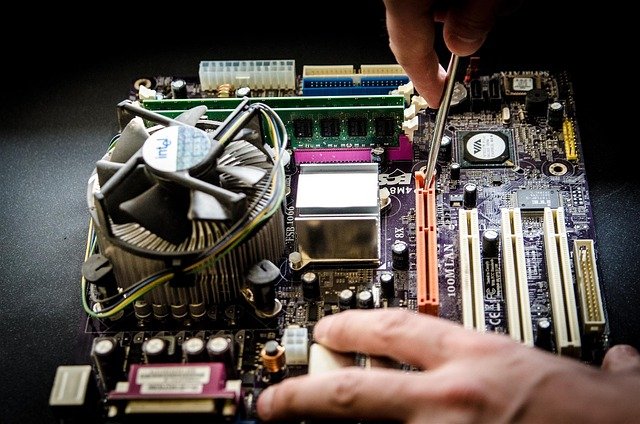

Managing Thermal Paste: Application and Replacement Intervals

Thermal paste is a small component with a big role in keeping processors and GPUs within safe operating temperatures. Proper application and timely replacement maintain performance, extend component life, and help avoid thermal throttling or instability. This article explains when to reapply paste, how it interacts with cooling systems, and practical recycling tips.

How thermal paste impacts CPU and GPU temperatures

Thermal paste fills microscopic gaps between a CPU or GPU die and the heatsink or cooler base, improving heat transfer by replacing trapped air with a thermally conductive medium. A correct application reduces junction-to-ambient thermal resistance, which in turn lowers operating temperatures and reduces the risk of thermal throttling. For modern multi-core CPUs and high-performance GPUs, even a few degrees can influence sustained boost behavior and long-duration workload stability. Using a paste compatible with your cooler material (aluminum vs. copper) and ensuring the contact surface is clean are fundamental steps to achieving consistent thermal performance.

How often to replace thermal paste for different hardware

Replacement intervals depend on paste type, operating conditions, and component usage. Standard silicone- or zinc-oxide-based pastes often remain serviceable for three to five years under typical desktop loads. High-performance or liquid metal compounds can last longer thermally but may require earlier replacement if removed during maintenance, or sooner if they risk corrosion with certain heatsink metals. Systems that run hot, operate 24/7, or are exposed to dust and poor ventilation may need inspection and reapplication every two to three years. Laptops, due to compact cooling and higher heat cycles, often benefit from more frequent checks, roughly every two years.

Does thermal paste affect SSDs, NVMe, and storage latency?

Thermal paste itself does not directly affect storage media like SSDs or NVMe drives, but thermal management can influence storage behavior. High-speed NVMe SSDs under sustained loads can heat up, causing thermal throttling that increases latency and reduces throughput. Some NVMe modules use dedicated thermal pads or small heatsinks rather than paste; in cases where a heatsink contacts a controller or NAND, using an appropriate thermal interface material matters. For storage, prioritize good case airflow and dedicated cooling measures over relying on paste; ensuring consistent temperatures helps maintain latency and throughput for SSDs and NVMe devices.

What role do cooling and airflow play with thermal paste?

Thermal paste is only one part of a complete cooling chain: the cooler, heatsink design, fan performance, case airflow, and ambient temperature all influence final results. Even the best-applied paste cannot compensate for poor airflow or undersized coolers. Proper airflow routes heat away from heatsinks and storage devices, preventing heat buildup that would undermine conductive advantages provided by the paste. When designing a system, balance intake and exhaust fans, avoid obstructing airflow with cables, and consider dust filters and periodic cleaning. Regularly check fan curves and monitor temperatures under load to detect airflow or cooling defects early.

Are BIOS and firmware relevant to thermal management?

Yes. BIOS and firmware settings can influence how aggressively fans respond to temperature changes and whether CPUs or GPUs throttle under thermal stress. Many motherboards expose fan curve controls, pump headers, and temperature offsets that let you tune cooling response. Firmware updates for SSDs and platform firmware for motherboards and power supplies can also improve thermal reporting and management, fixing issues that cause incorrect throttling or reporting. Keep BIOS and device firmware reasonably up to date, but avoid major updates during urgent operational windows; read changelogs for thermal-related fixes before applying them.

How to handle old paste and recycling considerations

When replacing thermal paste, remove old material carefully with isopropyl alcohol (90%+ preferred) and lint-free wipes to avoid residues that degrade contact. For liquid metal compounds, take additional precautions: they are electrically conductive and can corrode aluminum, so inspect for spread onto PCB traces and clean thoroughly. Recycling considerations are twofold: used thermal paste may contain metal oxides or other compounds that belong in hazardous or electronic waste streams in some jurisdictions, so avoid discarding it in general trash. Collect wiped materials and contaminated wipes in sealed bags and follow local e-waste and hazardous waste guidelines. Many electronics recycling centers accept small amounts of thermal interface materials along with other electronic components.

Practical maintenance tips and troubleshooting

When applying paste, use a small, even amount — typically a pea-sized dot for standard desktop CPUs — and avoid over-application which can reduce effectiveness or spread onto sockets. After reassembly, monitor idle and load temperatures with reliable tools and run a stress test to confirm stable behavior and expected delta between die and ambient temperatures. If temperatures are higher than expected, recheck contact pressure, heatsink seating, fan operation, and airflow direction. Keep records of paste brands, application dates, and observed temperature baselines to build a maintenance schedule tailored to your hardware and usage patterns.

Conclusion Proper application and periodic replacement of thermal paste support stable temperatures and performance across CPUs, GPUs, and thermally sensitive components. Consider paste type, operating patterns, and the broader cooling ecosystem—airflow, fans, and firmware—when planning maintenance. Responsible cleaning and disposal practices also help reduce environmental impact while keeping devices running reliably.